non-destructive testing (ndt)

visual testing (vt)

VT is the most common NDT method. It is a method where a weld is examined with the naked eye to evaluate the presence of surface discontinuities.

Examination can be performed quickly

Minimal equipment required

Cost effective

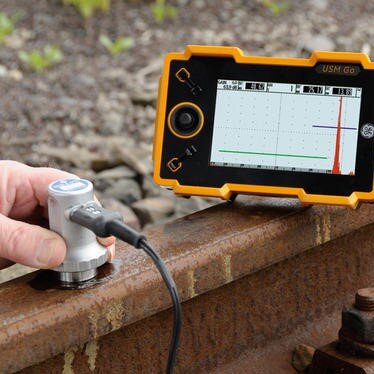

Ultrasonic testing (UT)

UT is a technique that utilizes high frequency sound waves to detect flaws in parts or materials.

Depth of penetration for flaw detection is superior to other NDT techniques

Highly accurate in determining position, size, and shape of discontinuities

Sensitive to both surface and subsurface discontinuities

magnetic particle testing (MT)

MT is a method that applies a magnetic field to a part or material to detect discontinuities.

Can detect both surface and near-surface indications

Low-cost compared to other NDT methods

Relatively fast method of examination

liquid penetrant testing (pT)

PT is a procedure that checks for material flaws by flowing liquid into the flaw and then drawing the liquid out with a developer.

Quick and inexpensive inspection of large areas and large volumes of parts or materials

High sensitivity to small surface discontinuities

Easy inspection of parts with complex shapes